Product Description

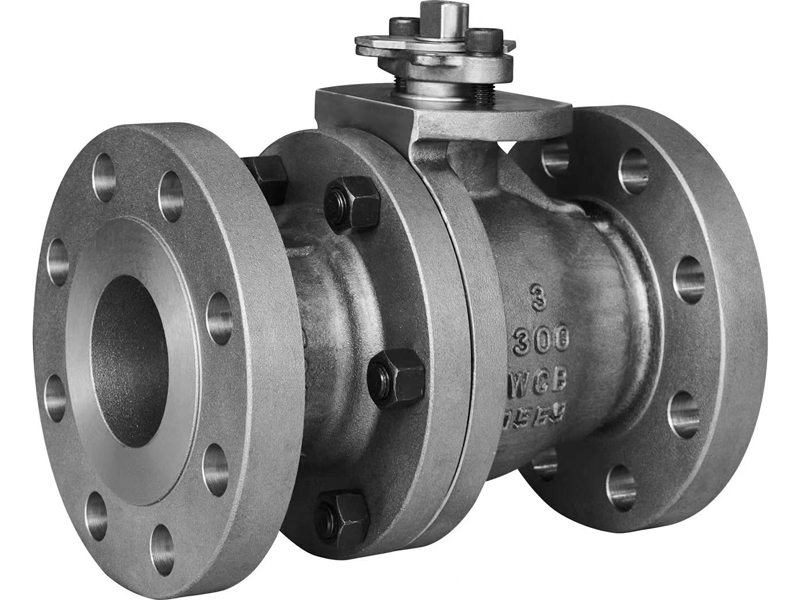

Cast steel floating ball valve 2pcs body lever operation, Material body WCB, ball F316, seat RPTFE, size 4IN class300LBS RF, full port, ASME B16.5, NACE MR0175, API 6D, API-607 Floating Ball valve series QILONG has ranges of of floating ball valves in different types, materials and designation with good quality and effective cost for general shutoff pipelines. Ball valves are widely used in our petroleum, chemical, electric power, boiler, water treatment and other industries. Floating ball type design is applicable to small size or low pressure ball valves, it has the forged or cast steel material form, valve body structure of 2 pcs or 3pcs. In comparison of trunnion ball valve, floating ball valve is always small size valves not bigger than 6 inch. Flange end floating ball valve pressure recommend size: 150LBS size 1/2IN~8IN, 300LBS size 1/2”~6IN 600LBS size 1/2 IN~3IN, 900~1500LBS size 1/2IN~2IN.

The biggest difference between a full bore ball valve and a reduced bore ball valve is that the full bore ball valve is the valve flow port bore and end connection bore diameter same as the pipeline diameter, and its size cannot be less than the value specified in the standard, which is almost equivalent to the nominal diameter of this specification. For example, the flow passage diameter of a DN 80 full bore ball valve is about 80 mm. The flow port bore of the reduced diameter ball valve is wider than the channel diameter, and the actual channel diameter is about one specification smaller than this specification. For example, the DN50 reduced diameter ball valve flows to about 38, which is roughly equivalent to the DN40 specification.

The biggest difference between a full bore ball valve and a reduced bore ball valve is that the full bore ball valve is the valve flow port bore and end connection bore diameter same as the pipeline diameter, and its size cannot be less than the value specified in the standard, which is almost equivalent to the nominal diameter of this specification. For example, the flow passage diameter of a DN 80 full bore ball valve is about 80 mm. The flow port bore of the reduced diameter ball valve is wider than the channel diameter, and the actual channel diameter is about one specification smaller than this specification. For example, the DN50 reduced diameter ball valve flows to about 38, which is roughly equivalent to the DN40 specification. Product case

Super Duplex steel grade 4A API6 D Ball valve 4IN 150LBS Top flange ISO 5210 ready for actuator

What are the advantages of forged ball valves vs cast ball valves, and how to choose the correct type of ball valve. Cast ball valve is a ball valve that is cast in a mold after melting steel in a furnace. Forging ball valve is to use forging machinery to exert pressure on the metal blank to produce plastic deformation, so as to obtain forgings with certain mechanical properties, certain shape and size. ● Casting ball valves can be cast into large diameter ball valves, and castings have higher requirements on the casting process. A feature of cast ball valves is that they can be made into more complex shapes. For valve body structure and irregular flow channel, casting can be formed at one time. Therefore, as long as the technology is passed, the large diameter valve body can be cast. ● The compactness of the forged ball valve is relatively good, because the flow channel and appearance are too complicated, it is impossible to form at one time, and it often needs to be modularized, forged separately, and connected together. ● Cast ball valves are often used for conventional pressures above DN50 and below 6.4MPa; forged ball valves should be used for DN50 and above 6.4MP for better performance.

What are the advantages of forged ball valves vs cast ball valves, and how to choose the correct type of ball valve. Cast ball valve is a ball valve that is cast in a mold after melting steel in a furnace. Forging ball valve is to use forging machinery to exert pressure on the metal blank to produce plastic deformation, so as to obtain forgings with certain mechanical properties, certain shape and size. ● Casting ball valves can be cast into large diameter ball valves, and castings have higher requirements on the casting process. A feature of cast ball valves is that they can be made into more complex shapes. For valve body structure and irregular flow channel, casting can be formed at one time. Therefore, as long as the technology is passed, the large diameter valve body can be cast. ● The compactness of the forged ball valve is relatively good, because the flow channel and appearance are too complicated, it is impossible to form at one time, and it often needs to be modularized, forged separately, and connected together. ● Cast ball valves are often used for conventional pressures above DN50 and below 6.4MPa; forged ball valves should be used for DN50 and above 6.4MP for better performance.